Welcome to our blog

Where we delve into the world of industrial caster wheels! These unassuming yet essential components play a significant role in various industries, revolutionizing the way we move heavy loads, equipment, and machinery. Whether you’re involved in manufacturing, warehousing, logistics, or any industry that requires efficient material handling, understanding the benefits and types of industrial caster wheels can greatly enhance your productivity. So, let’s explore the fascinating world of these wheels that keep industries rolling smoothly!

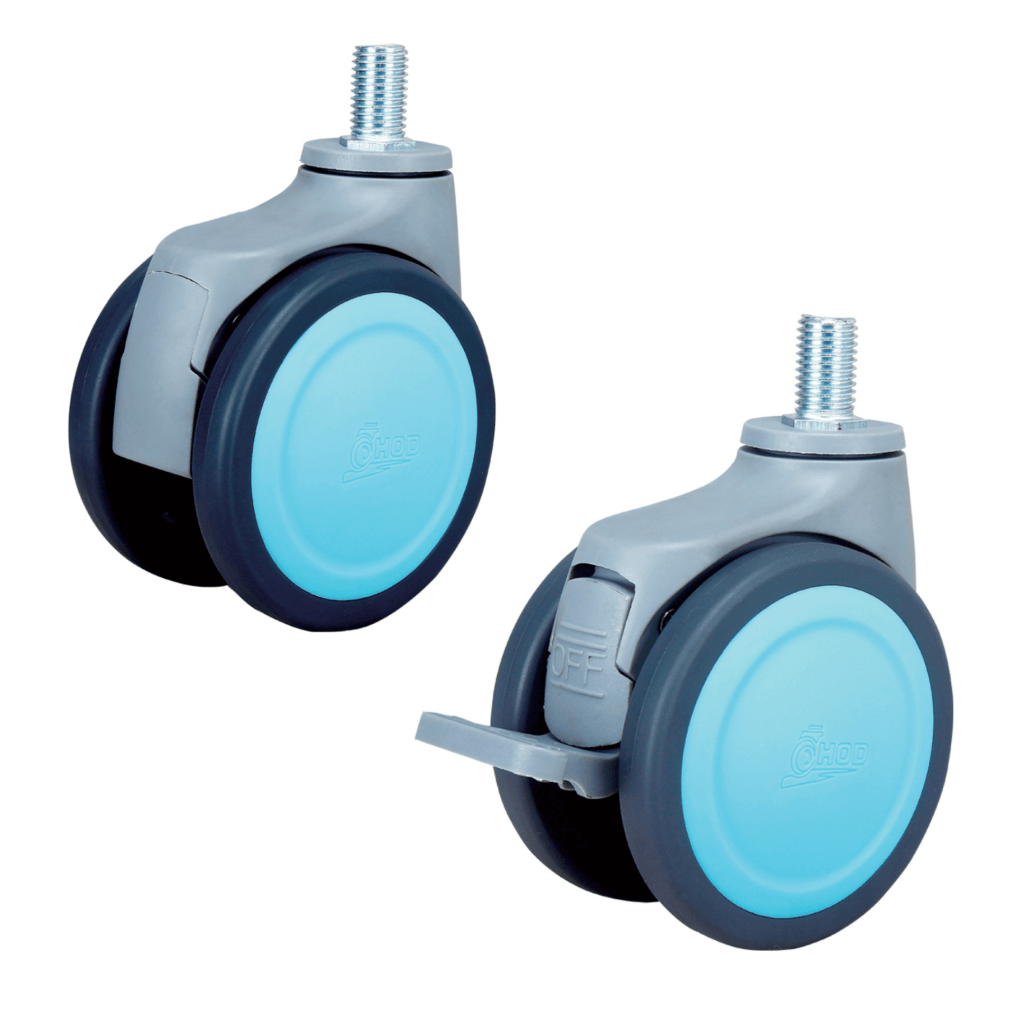

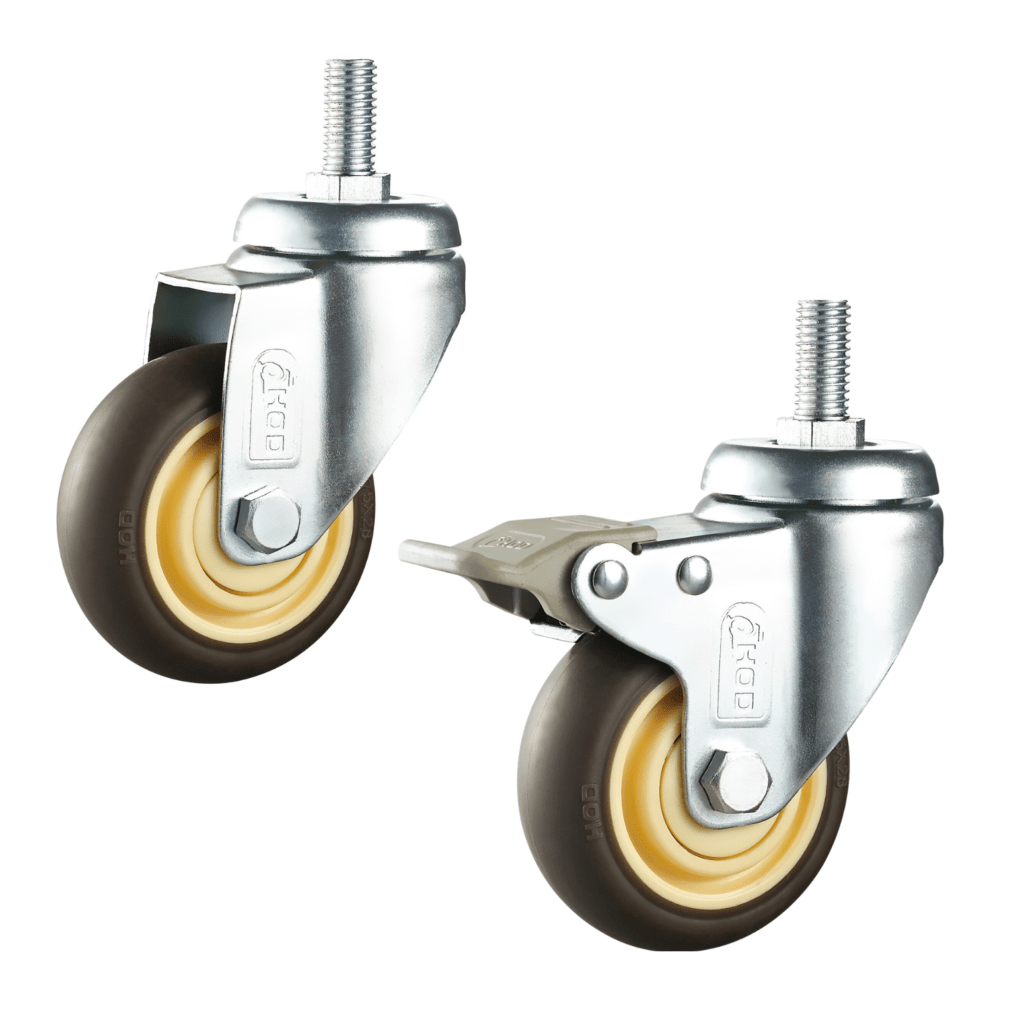

The Basics: What are Industrial Caster Wheels? Industrial caster wheels are specialized wheels designed to facilitate the movement of heavy loads in industrial environments. Composed of a wheel mounted on a rotating mechanism, these wheels offer versatility and durability for a wide range of applications. They are available in various sizes, materials, and designs, allowing you to choose the most suitable option for your specific needs.

Enhanced Mobility: Industrial caster wheels provide effortless maneuverability, allowing you to move heavy loads with ease. Their swivel functionality enables multidirectional movement, making them ideal for navigating tight spaces and crowded areas. we creates all types of caster wheels and we also customized any kind of caster wheels according to our valuable Clients.

Types of Industrial Caster Wheels: These wheels have a 360-degree swivel mechanism, allowing unrestricted movement in any direction. They are commonly used when maneuverability and flexibility are essential Rigid caster wheels provide stability and straight-line movement. They are suitable for applications that require a fixed direction of travel, such as conveyor systems or straight-line assembly lines.

What material is right for your caster wheels?

Finding the proper material for your castor wheels is crucial, and you should always choose the one that best suits your requirements. With that in mind, there are a variety of solutions that might be available; the key is choosing the best one for your needs. Nevertheless, each material has advantages and disadvantages of its own, so you must make every effort to choose carefully. In order to help you choose the appropriate material, we’ve listed some of the most popular ones used for castor wheels.

- Pneumatic/solid/semi – This material is very suitable for things like uneven or rough surfaces and it also gives you proper cushioning, which is always a plus. You can use them on outdoor surfaces and they work great on soft floors too, since they bring added protection. This can be a good option even if you want to use the castor wheels on grass for some reason..

- Plastic and Nylon –There are a lot of benefits you get from these castor wheels. They have chemical resistance, easy rolling and a really good capacity. They are similar to polyurethane when it comes to high loads, but the added chemical resistance can really help make a huge difference in a situation like this.

- Polyurethane – As we mentioned above, these are the best for high loads. This type of castor wheels will outlast most of the castor wheels on here, and the best part about them is that they also offer quiet operation and floor protection. To make things even better, these are liquid cast onto aluminum or cast iron, which is incredibly helpful and convenient.

- Rubber – You can go with rubber castor wheels since they are pretty durable and the overall results you get are pretty impressive. To make things even better, they can be molded to plastic, aluminum or iron as well. It’s a very good option and one that you do not want to miss.

- Metal – Metal castor wheels have a very good tensile strength and capacity, which makes them good especially for the high heat applications. You get easy rolling, however they can damage soft flooring. As a result, you will use these mostly for the more durable floor types. The load capacity is very high in this situation, which makes such a material highly sought after.

- Conclusion – It’s always a very good idea to take your time as you try to pick the best castor wheels material out there. As you can see, every material has specific features, so you need to think about those features as you try to get the best outcome. It’s not an easy thing to achieve, but that’s why you have to study the material as much as you can in order to obtain the best results and experience. It’s not going to be easy, but you will find it incredibly rewarding in the long term. Also, make sure that you think about the material finish and how it matches the castor wheels, as that can also make a huge difference!

Contact ProCastor wheels today to select the right castor wheel material for your business or application. Call us or email us at sales@procasterwheels.com